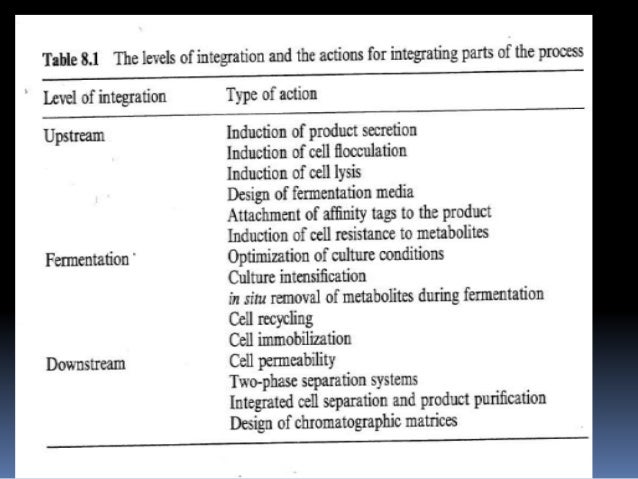

Chromatographic methods: it is generally, used for the purification of low molecular mass compound from mixture of similar molecules, e.g., antibiotics(homologous) and macromolecules (enzymes).Crystallization: This is used for the low molecular mass compound like antibiotics.Purification is achieved by the following procedures:

It aims at recovery of the product in a highly purified state.Ion exchange resins:g.- Dextran cellulose, polyamine, acrylate etc.Membrane filtration:g.- Microfiltration, ultrafiltration, reverse osmosis and electrodialysis.Evaporation: E.g.- continuous flow evaporator, falling film evaporator, thin film evaporator, spray dryers.It is generally achieved by the following: Some of the product concentration may occur during the extraction step.Whole broth (medium + cells) extraction.The process of extraction is achieved by: The process of extraction is frequently useful for the recovery of Antibiotics and most of the lipophilic substances.

It usually achieved both separation of particles as well as concentration of the product.It involves the recovery of a compound or a group of compounds from a mixture or from cells into a solvent phase.Lysis: lysis of microbial cells may be achieved by chemical means, e.g., salt or surfactants, osmotic shock, freezing, or Lytic enzymes, e.g., lysozyme, etc.Drying: it involves the drying of cells by adding the cells into a huge amount of cold acetone and extracted using buffer or salt solution.Mechanical cell disruption: this involves the uses of shear, E.g.-, colloid mill, ball mill grinder etc., homogenizer and ultrasound.Disruption of microbial cell is usually difficult because of their small size, rigid cell walls and high osmotic pressure inside the cells.ĭisruption of cell is generally achieved by mechanically, lysis or drying:.Flotation: in any case, the gas bubble need to adsorb and surround the cell, raising the gas bubbles to the surface of media in the form of foam.If flocculation isn’t effective than very minute gas bubbles is made by sparging, release of over pressure or electrolysis.Flocculation: It involves the aggregation of cells which may be induced by inorganic salt, minerals, hydrocolloids and organic polyelectrolytes.Flocculation and flotation– It is used for small bacterial cells which are difficult to separate even by centrifugation.Centrifugation– It may be used for bacteria, usually, protein precipitates.Filtration– it is used for filamentous fungi and bacteria.ĭifferent techniques of filtration are as follows:.It is generally achieved by following ways: It is first step of DSP and usually involve the separation of solids substances, from the liquid media.

0 kommentar(er)

0 kommentar(er)